3LPs

Retail ERP and POS and E-Commerce Logistics Management

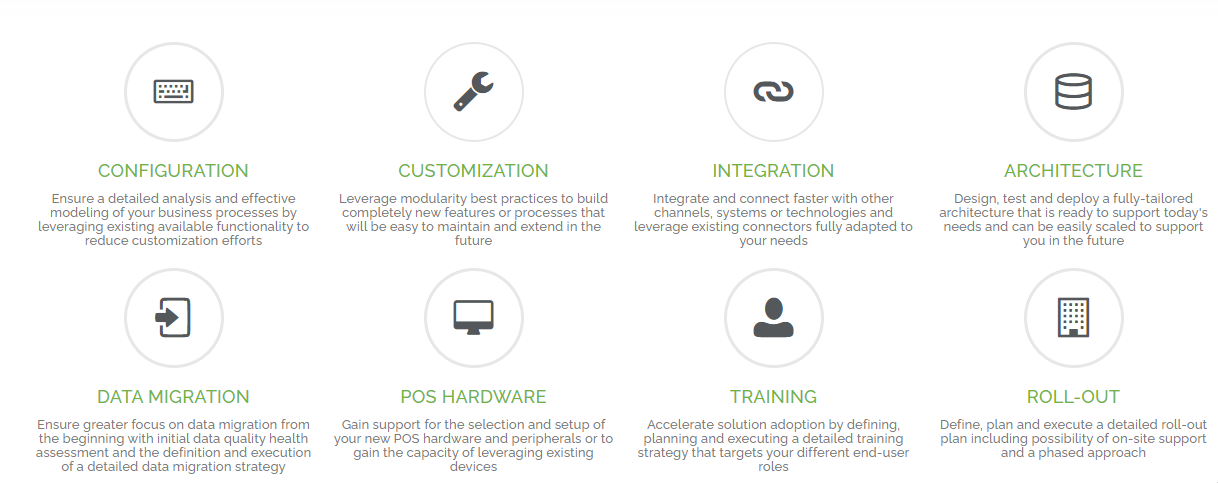

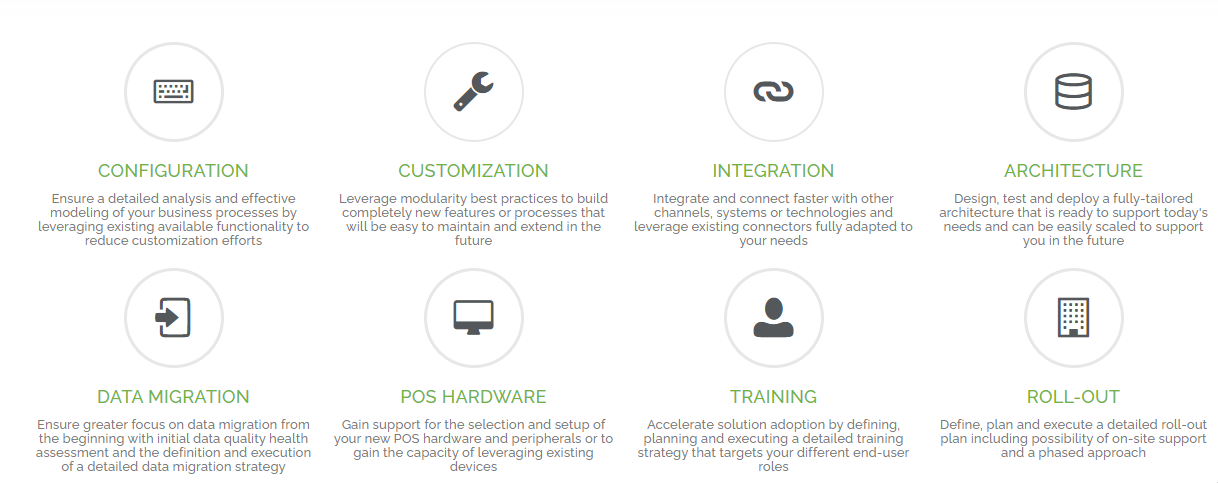

We provide Retail ERP and POS E-Commerce

ERP + 3Lps + E-Commerce + Delivery + Payment Processing

Customization tool

Click and change content directly from the front-end: no complex back

end to deal with.

Building blocks system

Create your page from scratch by dragging and dropping pre-made,

fully customizable building blocks.

MES

Manufacturing Business Solutions That Support Your Growth and Expansion

Industry 4.0 ~ 5.0

The use of robots in manufacturing has been on the rise since the 1960s, when they were first introduced as part of what technologists call Industry 3.0 (defined by programmable logic and advanced manufacturing). Robots grew up in the car industry, where they were used primarily to weld car bodies together. As technologies matured, companies began using robots in other areas, such as logistics and the medical and food industries. Starting in 2006, more robots were used outside the automotive industry than inside it.

Robots improve the consistency of product quality and production line flow, meeting demand for high-quality products at lower cost.

They save workers from having to perform repetitive, tedious, and dangerous tasks.

Today's connected, or Industry 4.0, robots are able to consistently generate data on parts flow and process quality-data that artificial intelligence or old-school data analysis can use to optimize both a factory and manufacturing processes.

Thanks to greater inherent flexibility than special machines or other hard automation, robots enable greater product variation on a single line and-when integrated with logistics systems in Industry 4.0 setups-enable factories to produce variants based on the customer's choice of preconfigured options (often referred to as "mass customization").

Because robots cost almost the same everywhere in the world, they can help companies reshore manufacturing jobs that were transferred to low-cost labor countries and generally level the playing field.